Test & Tag

Electrical appliance & RCD testing

Electrical safety is paramount and it is your responsibility as a PCBU to ensure you take all practical measures to protect staff and customers from electrocution, fire, and other injuries caused by hidden faults. Electrical safety test and tagging is the process by which electrical equipment is inspected and tested for safety according to the intervals set out in the AS/NZS 3760 and AS/NZS 3012 Standards.

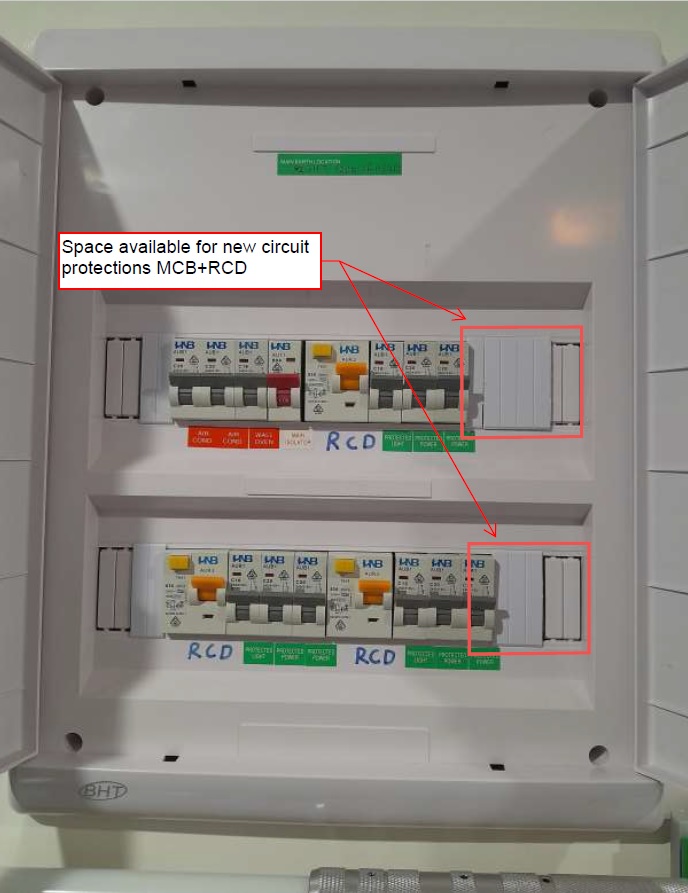

Any electrical equipment that is connected to the electrical supply by a flexible cord and/or connecting device requires electrical safety testing and tagging which varies according to the type of environment and/or equipment. AS/NZS 3760 also sets out the requirements for the testing of Residual Current Devices (RCDs). An RCD should be installed to most circuits supplying electricity to power outlets and is designed to prevent persons from receiving a potentially fatal electric shock should they come into contact with faulty equipment.

RCDs require regular testing, typically at 3 or 6 month intervals, to ensure they will disconnect the electrical supply to protect users in the event of a fault. As a PCBU, testing and tagging of equipment to AS NZS 3760 or AS/NZS 3012 as applicable, will ensure you can demonstrate that reasonably practicable measures have been taken to eliminate potential electrical hazards introduced by appliances. We can also provide advice and training for users to promote awareness of electrical safety in the workplace.